-

Rolamentos de esferas cerâmicos

-

608 rolamentos cerâmicos

-

Rolamentos cerâmicos híbridos

-

Rolamento do carboneto de silicone

-

Rolamento de deslizamento cerâmico

-

Rolamentos de rolo cerâmicos

-

Rolamento empurrado cerâmico

-

Cerâmica estrutural avançada

-

Bola do nitreto de silicone

-

Bola do carboneto de silicone

-

Bola cerâmica da zircônia

-

Rolamentos de esferas do carboneto de silicone

-

Rolamento de esferas do nitreto de silicone

-

Rolamento cerâmico da zircônia

-

Selagem mecânica

-

RobertaSeus rolamentos cerâmicos são da elevada precisão, bons qualidade e barato. Nós temos a cooperação por muitos anos.

RobertaSeus rolamentos cerâmicos são da elevada precisão, bons qualidade e barato. Nós temos a cooperação por muitos anos. -

Olga WeinbergEsta empresa é nosso segura e o fornecedor profissional dos rolamentos cerâmicos por muitos anos, seus rolamentos cerâmicos, que são usados em nossa bomba é bom na qualidade.

Olga WeinbergEsta empresa é nosso segura e o fornecedor profissional dos rolamentos cerâmicos por muitos anos, seus rolamentos cerâmicos, que são usados em nossa bomba é bom na qualidade.

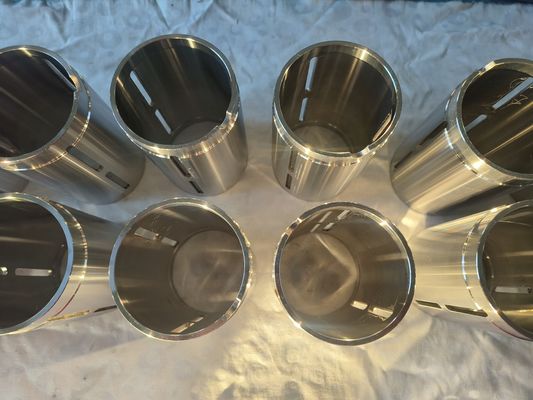

Bolsas de rolamento de aço inoxidável personalizadas para bomba

| Lugar de origem | China |

|---|---|

| Marca | CSQ |

| Certificação | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Número do modelo | Personalizado |

| Quantidade de ordem mínima | 20-50 PCs |

| Preço | negotiable |

| Detalhes da embalagem | Caixa de espuma+Cartom |

| Tempo de entrega | 20-45 dias de trabalho |

| Termos de pagamento | T/t, t/t |

| Habilidade da fonte | 2000 PCs por mês |

| Nome | Manga de expansão de aço inoxidável | Categoria | Cerâmica estrutural avançada |

|---|---|---|---|

| Material | Aço inoxidável | Precisão | Personalizado, de acordo com os desenhos |

| Tamanho | Personalizado | PACAGE | Caixa de espuma+Cartom |

| Destacar | Bucha de rolamento de aço inoxidável para máquinas de alimentos e bebidas,Rolamento liso para equipamentos farmacêuticos e médicos,Manga de expansão para equipamentos químicos e petroquímicos |

||

Uma bucha de manga de aço inoxidável, também conhecida como bucha de rolamento de aço inoxidável ou rolamento plano, é um componente mecânico cilíndrico feito de aço inoxidável.A sua função principal é suportar eixos rotativos ou recíprocos, servindo como uma parte de desgaste sacrificial que protege o eixo mais caro e equipamento de alojamento.

Sua principal vantagem sobre as buchas de aço padrão é sua excepcional resistência à corrosão, tornando-a adequada para ambientes úmidos, químicos e aplicações com altos requisitos de higiene.

O desempenho da bucha é determinado principalmente pela sua qualidade de aço inoxidável.

- 304 aço inoxidável:Um aço inoxidável austenítico versátil com boa resistência à corrosão (especialmente em ambientes atmosféricos e químicos suaves), formabilidade e dureza.Indústria química geral, equipamentos de exterior e outros ambientes não severamente corrosivos.

- 316 aço inoxidável:Contém molibdênio (Mo), que aumenta significativamente a resistência aos cloretos (por exemplo, água do mar, salmoura) e a uma gama mais ampla de produtos químicos em comparação com 304.Farmacêutico, equipamento de processamento químico e de branqueamento onde a resistência à corrosão é crítica.

- Excelente resistência à corrosão:Resiste à umidade, a vários produtos químicos e não enferruja.

- Alta resistência e dureza:Capaz de suportar certas cargas e impactos.

- Higiênico e não tóxico:Fácil de limpar, em conformidade com os padrões da indústria alimentar e farmacêutica.

- Resistência à temperatura:Mantenha um desempenho estável numa ampla gama de temperaturas.

As carcaças de mangas de aço inoxidável são amplamente utilizadas em várias indústrias que exigem prevenção de ferrugem e resistência à corrosão:

- Máquinas de alimentação e bebidas: Enchimentos, misturadores, transportadores, etc., onde a contaminação deve ser evitada e a fácil limpeza/sanitização é essencial.

- Equipamento farmacêutico e médico: Padrões de higiene extremamente elevados, necessitando de suportar vários agentes de limpeza e processos de esterilização.

- Equipamento químico e petroquímico: localizações de rolamentos em bombas, válvulas e agitadores, resistentes à corrosão de meios químicos.

- Engenharia marítima e offshore: máquinas de convés, componentes de hélice em navios, resistentes à água do mar e spray de sal.

- Equipamento de tratamento de águas e proteção ambiental: tratamento de esgotos, bombas de água e outros ambientes úmidos/químicos.

- Máquinas têxteis e de papel: Operando em ambientes de alta umidade, alta temperatura ou contendo alvejante.

O logotipo da nossa empresa é ZXSQ e CSQ, e possui onze patentes de invenção para modelos de utilidade.Para lhe fornecer um serviço de alta qualidade e perfeito, de acordo com as exigências do cliente para encomendar uma variedade de produtos de rolamentos.

Desde o ano de 1982 temos acumulado uma experiência rica na produção ao longo dos últimos mais de 40 anos,dedicando-nos de todo o coração à pesquisa e desenvolvimento de material de rolamento cerâmico, a nossa técnica de processamento e a melhoria dos nossos equipamentos.

Tendo sofrido várias evoluções e transformações, a nossa empresa tornou-se agora a empresa líder no mercado interno da China nos campos de rolamentos cerâmicos e produtos de materiais cerâmicos.

Atualmente, temos uma linha de produção de moagem e montagem totalmente automática para rolamentos cerâmicos, com uma produção anual de 3 milhões de conjuntos de 608-2PS,608-2RS e outras especificações dos níveis de precisão P5 e P4.

A nossa empresa tem o equipamento mais avançado no campo da produção de cerâmica industrial doméstica,para além do forno de sinterização isostática a quente (HIP) importado da ABB SuéciaA nossa empresa dispõe também de outros equipamentos de produção, a temperatura de cozimento do produto foi elevada para mais de 2000°C.

R: Somos uma fábrica em Pequim, na China. Produzimos e vendemos rolamentos cerâmicos há mais de 40 anos.Estabelecemos relações de cooperação amigáveis com muitas empresas nacionais e estrangeiras..

A: Nós sempre produzimos amostras antes da produção em massa, e produzir em estrita conformidade com os requisitos do cliente e regulamentos de produção.Usaremos equipamentos de inspeção para realizar uma inspeção precisa dos produtos, e a nossa embalagem adota o seguro duplo de espuma e cartão, para garantir estritamente a qualidade dos produtos.

A: Rolamentos de esferas de ranhuras profundas de cerâmica, rolamentos de esferas de contacto angulares de cerâmica, rolamentos de esferas de cerâmica híbridos, rolamentos de cerâmica lineares, etc. e todos os tipos de esferas de cerâmica.

R: Somos uma empresa integrada na indústria e no comércio, temos três fábricas, com o equipamento de produção e inspeção de hoje, podemos fornecer melhores datas de entrega e qualidade do produto.

A: Nós forneceremos produtos de alta qualidade e serviços personalizados, que podem ser totalmente personalizados de acordo com as necessidades do usuário.

Nós fornecemos rolamentos, produtos de alta qualidade, se você precisa comprar ou consultar o preço de rolamentos, por favor, entre em contato conosco.Serviço numa das empresas de rolamentos profissionaisNós escolhemos matérias-primas de alta qualidade, cuidadosamente fazer cada conjunto de rolamentos.

Nós aderimos à demanda do cliente como a orientação, e nos esforçamos para fornecer aos clientes produtos de qualidade e serviço pós-venda, criar valor para os clientes, fazer os clientes parceiros.Bem-vindo a discutir a cooperação!

Classificação geral

Instantâneo de classificação

A seguir está a distribuição de todas as classificaçõesTodos os comentários