Todos os Produtos

-

Rolamentos de esferas cerâmicos

-

608 rolamentos cerâmicos

-

Rolamentos cerâmicos híbridos

-

Rolamentos de rolo cerâmicos

-

Rolamento empurrado cerâmico

-

Rolamento de deslizamento cerâmico

-

Cerâmica estrutural avançada

-

Bola do nitreto de silicone

-

Bola do carboneto de silicone

-

Bola cerâmica da zircônia

-

Rolamentos de esferas do carboneto de silicone

-

Rolamento de esferas do nitreto de silicone

-

Rolamento cerâmico da zircônia

-

Selagem mecânica

-

Rolamento do carboneto de silicone

-

RobertaSeus rolamentos cerâmicos são da elevada precisão, bons qualidade e barato. Nós temos a cooperação por muitos anos.

RobertaSeus rolamentos cerâmicos são da elevada precisão, bons qualidade e barato. Nós temos a cooperação por muitos anos. -

Olga WeinbergEsta empresa é nosso segura e o fornecedor profissional dos rolamentos cerâmicos por muitos anos, seus rolamentos cerâmicos, que são usados em nossa bomba é bom na qualidade.

Olga WeinbergEsta empresa é nosso segura e o fornecedor profissional dos rolamentos cerâmicos por muitos anos, seus rolamentos cerâmicos, que são usados em nossa bomba é bom na qualidade.

Pessoa de Contato :

Cooper wang

Número de telefone :

86 15801087509

Sliding Bearing SiC Sleeve for Canned Motor Pump

| Lugar de origem | CHINA |

|---|---|

| Marca | CSQ |

| Certificação | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Número do modelo | produtos personalizados |

| Quantidade de ordem mínima | 20-50 PCs |

| Preço | negotiable |

| Detalhes da embalagem | Caixa de espuma+caixa |

| Tempo de entrega | 20-45 dias de trabalho |

| Termos de pagamento | T/T. |

| Habilidade da fonte | 2000pcs por mês |

Contacte-me para amostras grátis e vales.

Whatsapp:0086 18588475571

bate-papo: 0086 18588475571

skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

xDetalhes do produto

| Nome | Rolamento deslizante de cerâmica personalizado | Categoria | Rolamento da bomba de cerâmica |

|---|---|---|---|

| Material | Carboneto de silício sinterizado sem pressionamento/zircônia | Tamanho | Personalizado, de acordo com os desenhos |

| Usar | Bomba de motor enlatada | Pacote | Caixa de espuma+caixa |

| palavra -chave | rolamento de bomba de motor enlatada | Tipo | Parte da transmissão crucial |

| Destacar | SiC sliding bearing for motor pump,ceramic sliding bearing sleeve,canned motor pump SiC bearing |

||

Descrição de produto

Sliding Bearing SiC Sleeve for Canned Motor Pump

Silicon Carbide (SiC) Sleeve and Thrust Disc Assembly

The Sleeve and Thrust Disc Assembly is a critical component of sliding bearings, serving as both the support and rotational unit in canned motor pumps. Silicon carbide (SSiC) is renowned for its outstanding corrosion resistance, wear resistance, and superior material properties, making it an ideal sliding bearing material for such pumps.

Key Features

- Superior Wear Resistance: High hardness and low friction coefficient of SiC (SSiC/SiC) ensure extended service life.

- Corrosion Resistance: Immune to acids, alkalis, and high-temperature fluids, ideal for aggressive media.

- Thermal Stability: Low thermal expansion maintains dimensional accuracy under high-speed rotation.

- Customizable: Available in standard or integrated designs to fit various pump models.

Typical Uses

- Chemical process pumps, nuclear coolant systems

- High-purity fluid transfer (e.g., semiconductor-grade chemicals)

- Sealless solutions for extreme pressure/temperature conditions

Main Applications of Canned Motor Pump

1. The canned motor pump can be used in common corrosive conditions, such as with inorganic matter, acid, alkaline and salt media. In such conditions, SSiC (sintered) is the standard sliding bearing material.

2. The canned motor pump can be used in common corrosive conditions with media that is prone to vaporization.

Key Properties of Pressureless Sintered Silicon Carbide

| Max Temperature | Up to 1650℃ |

| Density | 3.15-3.18 g/cm³ |

| Thermal Expansion | 4.0 (10-6/℃) |

| Thermal Conductivity | 120 W/m°K |

| Hardness | 2800 HV5 |

| Elastic Modulus | 410 GPa |

| Chemical Stability | Superior resistance to acid and alkali corrosion (including hydrofluoric acid) |

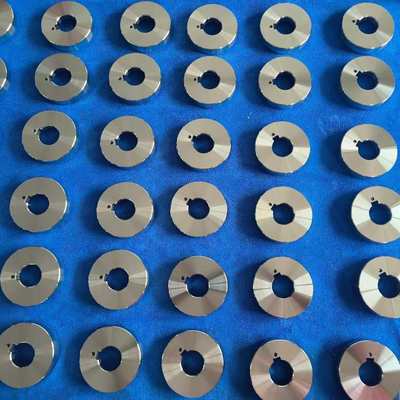

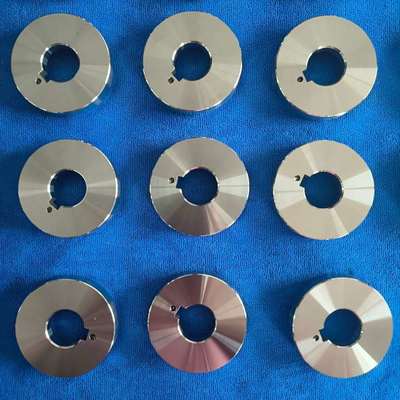

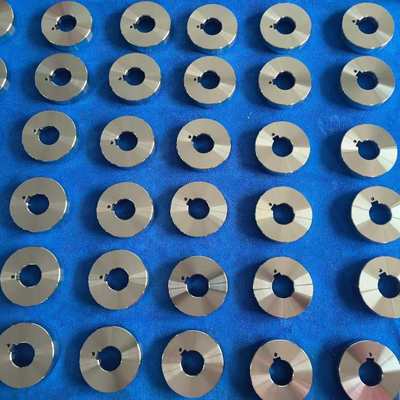

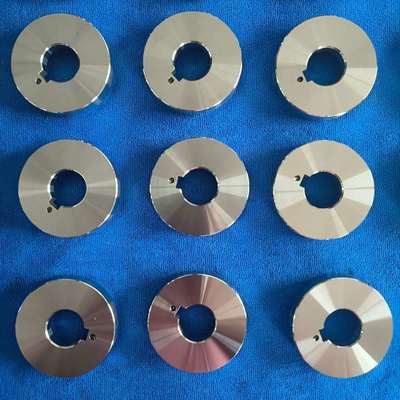

Product Images

Our Factory and Processing Capabilities

We operate three factories in China to meet diverse customer requirements, equipped with advanced pressing, sintering and processing machinery.

Produtos recomendados